CableGrid® is the exclusive distributor for the Brugg Cables Switzerland and KEI Cables India’s complete range of Cable and Accessories products in Australia and New Zealand.

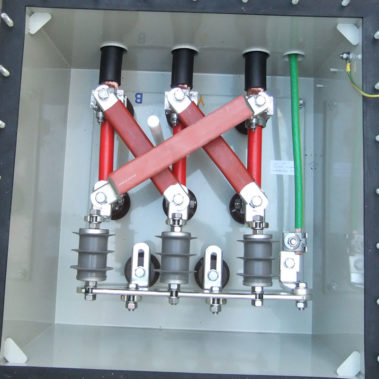

Brugg Switzerland Cable and Accessories range extends up to 550kV and includes Joints, GIS, Transformer and Outdoor Sealing Ends.

KEI Cables was established in 1968 and manufactures a wide range of cables from 415V – 1.1kV, 3.3, 6.6, 11, 22 and 33 – 36kV and 66kV, 110kV, 132kV, 220kV, 275kV, 330kV and 420kV under a licence agreement for Brugg Cables Switzerland.

KEI manufactures 60V – 1.1kV cables including: Instrument Cables with and without Nylon Jacket, Thermocouple, Extension/Compensating, Concentric bonding cables, Marine & Offshore Cables, Single/Multicore Flexible Wires, LV Power Cables XLPE and PVC, Single/Multicore Flexible Wires, Control Cables, EPR/Rubber Cables, Signal Cables, Earthing cables, Special cable for Oil and Gas, Mining cable and machine trailing cable 60V – 1.1kV…etc. These LV cables have been manufactures and type tested to various IEC, BS, AS/NZS standards and KEI has supplied 1000’s of km of LV cable into Australia since 2008.

KEI has a complete range of 3.3 – 36kV cables manufactured and tested to AS/NZS 1429.1 and AS/NZS:1429.2 and Independently Type Tested by KEMA.

KEI manufacturers cables under licence for Brugg Cables Switzerland for all 66kV -420kV cables. These cables are Independently Type Tested to IEC 60840 at 66 and 132kV and Independently Type Tested and PQ tested with Brugg accessories to IEC 62067 at 220kV and 420kV by CESI in Europe.

CableGrid® brings together the skills, knowledge and expertise of a great team of sales and installation personnel, with decades of combined experience in MV, HV and EHV cables, cable accessories and cable jointing, from 3.3 to 400kV AC and 80 to150kV DC.

Our business continues to combine the decades of experience of both our sales and cable jointing teams, to offer our clients the best outcome for their specific project requirements.

Furthermore, we can provide training for Utilities, that wish to purchase our 66, 132, 220, 275, 330, 550kV cable accessories or complete cable systems for XLPE and FFC/Oil filled cables.

CableGrid® as a company holds the necessary insurances to meet industry standards. Installation team members hold Contractors Licence, Electrical Jointing Licensing, State applicable Safety Induction Certificates and First Aid Certificates.