Introduction

Cable Grid trusted partner in developing, manufacturing and final testing of high voltage cables up to 500kV is Brugg, Switzerland. Brugg have a wealth of experience and draw on intensive research in their own high-voltage testing laboratory. As a result they can offer you a broad range of customer-specific polymer cables, as well as solutions for the current maximum voltage level of 500 kV. Brugg also offer an extensive range of accessories of excellent quality combined with winning, innovative, easy-to-install solutions.

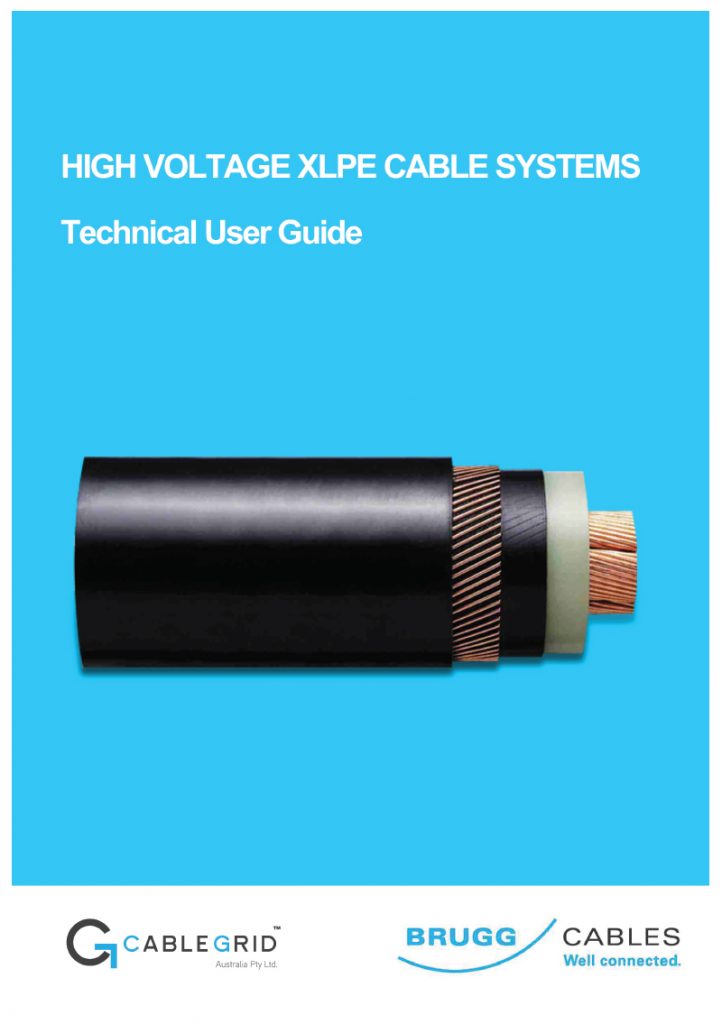

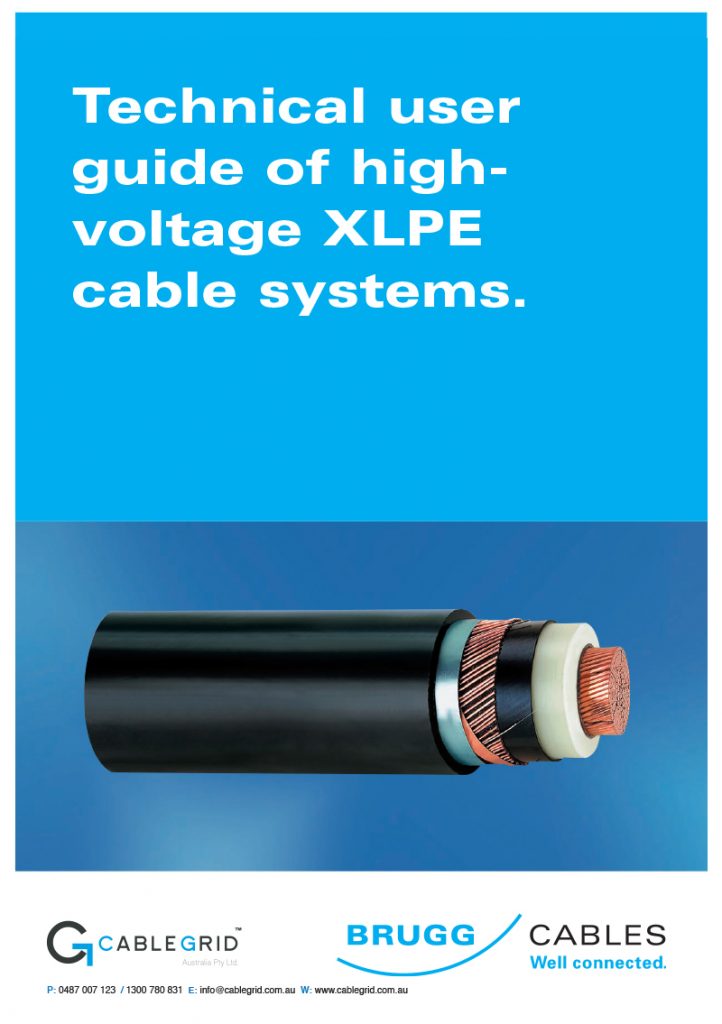

Cable: 66, 132, 220, 275, 330 & 500kV

Designed and Type Tested to IEC 62271.209

- Supply of 66 – 500kV XLPE Cu and Al cable made to IEC 60840 and other applicable standards

- Supply of 66 – 500kV XLPE cable accessories for, Corrugated Aluminium, Corrugated Stainless Steel, Corrugated Copper, Lead Sheath, APL, AWA, PVC, LDPE, MDPE, HDPE

Only high-quality accessories perfectly tailored to the power cables being used will guarantee a high level of operational safety for your cable systems. That’s why cable accessories like sleeves and sealing ends are key elements in a cable system. Maximum quality is vital in this area in particular, to ensure both operational safety and the service life of your cable system.

Joints & Terminations: 66, 132, 220, 275, 330 & 500kV

Designed and Type Tested to IEC 62271.209

- GIS Terminations: Dry Plug-in and Epoxy Resin Oil Filled GIS Terminations

- Transformer Terminations: Dry Plug-in and Epoxy Resin Oil Filled GIS Terminations up to 500kV

- Outdoor Porcelain and Composite (Silicone) Terminations (sealing ends) Oil filled and Dry type up to 500kV

- Blast proof Outdoor Porcelain and Composite (Silicone) Terminations (sealing ends) Oil filled and Dry type up to 500kV

- Joints: straight through, cross bonding, screen break, copper sleeves, fibreglass sleeves, resin filed or heat shrink out sleeves for tunnel applications up to 500kV

Jointing & Terminating of Power Cables & Installation:

Our installation team has decades of experience dating back to the 1980’s and has installed products from manufacturers in Switzerland, Italy, Germany, Sweden and Japan, ranging from 3.3 to 400kV AC and 80 to 150kV DC with conductor sizes from 16 to 2500mm², in both copper and aluminum. The team hassignificant experience both domestically with Electrical Transmission and Distribution Utilities, Mines, Renewable Energy & Wind Farms, Rail Networks…etc as well as internationally on projects in Iran, Qatar, UAE, Vietnam, India, Sweden and Chile.

CableGridjointers are trained and certified on numerous manufacturers Cable Accessories, a very important issue when it comes to confidence, versatility and reliability.

We will not install products, which we are not trained in and certified on.

Our team has the latest in technology and training and when it comes to specialised tooling and equipment, we ensure we have the best. We are always performing to the highest standards and efficiency.

The safety and welfare of our team and those working around them, is of the highest priority to CableGrid. Statutory training is carried out as required to ensure the validity of certificates of currency. Additionally, the care and maintenance of the worksites and surrounding environment is non-negotiable for our team. In addition to our own WHSE policies and procedures, we incorporate any specific WSHE requirements of the sites on which we work.